| Item Name | China Factory BDPAK Wholesale Glass Cream Jar Glass Airless Bottle Glass Dropper Bottle For Cosmetic Packaging |

| Details | Cream packaging |

| 1.Material:Outer Cap:PMMA;Inner Cap:PP;Outer Bottle:PMMA;Inner Bottle:PP;Lid:PMMA | |

| 2.With Liner | |

| 3.Usage: Cosmetics, skin care, lotion, gel, cream, etc. | |

| 4.Capacity options: 5ml;15ml;30ml;50ml;100ml;200ml | |

| Material | PP,PMMA,Glass |

| Color | Any color is available |

| Artwork Treatments | Color-spray painting, silk-screen printing, label sticker, etc. |

| Printing: | Hot printing/silk printing/offset printing |

| Type: | Cosmetic Jar |

| Surface Handling: | Screen Printing |

| Payment | 50% deposit, 50% TT before delivery |

| Lead Time | 30 days |

| MOQ | 5,000 pcs |

| Packing | Cartons or as per client’s requirements |

What are the cosmetic bottles:?

There are many types of cosmetic bottles. From the material point of view: glass bottles, plastic bottles, PET bottles

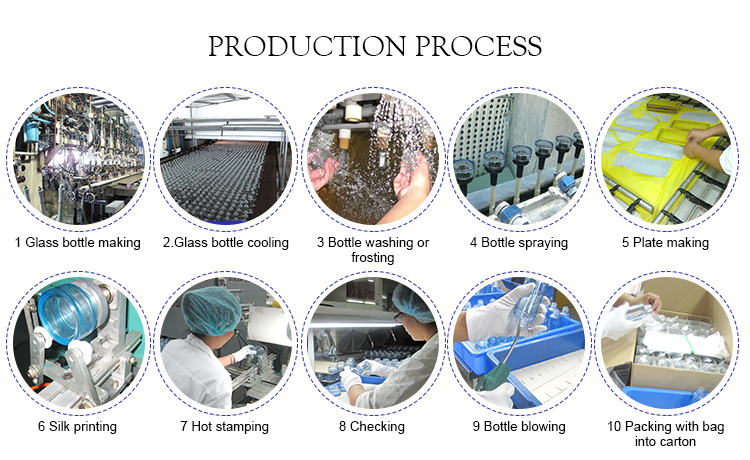

From the production process: injection molding bottles, blow molding bottles

From the product point of view: there are washing packaging, cream packaging

PET material is an environmentally friendly material with high barrier properties, light weight, non-breaking characteristics, chemical resistance, and strong transparency. It can be made into pearlescent, colored, magnetic white, and transparent. It is widely used in the field of gel water.

The material of plastic bottles is usually PP, PE, AS, ABS, acrylic, PET, etc. Acrylic is an injection-molded bottle, which has poor chemical resistance and is prone to cracks. It is not recommended to be used as a cosmetic bottle.

As a cosmetic bottle, the most ideal bottle is made of glass. In addition to good sealing performance, stable chemical properties, diverse shapes and beautiful colors, cosmetic glass bottles can be used as packaging for various high-end cosmetics.

The glass bottle has good chemical stability and is not easy to react with the contents; it has good transparency, and can add iron, cobalt, chromium and other colorants to the raw materials to produce glass bottles of various colors (such as amber glass, green glass, blue and white glass, Cobalt blue glass, opal white glass, opal glass); good heat resistance and not easy to deform; high compressive strength, resistance to internal pressure; high density and weight (suitable for higher-end cosmetic packaging); barrier properties, hygiene and Good preservation, easy to seal, tightly sealed again after opening. However, at the same time, glass bottles have poor impact resistance, fragility, high filling costs, and complicated molding and processing, which limits the application of glass bottles. Glass bottles are often used for packaging high-end cosmetics or some special cosmetics.

The glass bottles generally used for packaging liquid cosmetics are generally small-mouth bottles (narrow-mouth bottles), which are mainly used for packaging nail polish, nail polish remover, perfume and fragrance. The structure and shape of the glass bottle can be designed according to the needs of product packaging, and it can be realized by changing the mold during manufacturing. The bottle body can be directly decorated with printing or labeling. At the same time, glass bottles of different colors can be used to meet the packaging requirements of different characteristics of cosmetics.