|

Temperature difference

|

≥ 41℃

|

|

Air pressure inside bottle

|

≥1.4MPa

|

|

Surface processing

|

Frosted,Decal,Color Spray

|

|

Volume

|

5-100ml

|

|

Height

|

179mm-300mm or other

|

|

Color

|

Amber,Flint,Normal flint,Blue,Green or as request

|

|

Sealing Type

|

Crown cap, Screw Cap, Swing Top or Per Customer Request

|

|

Additional services

|

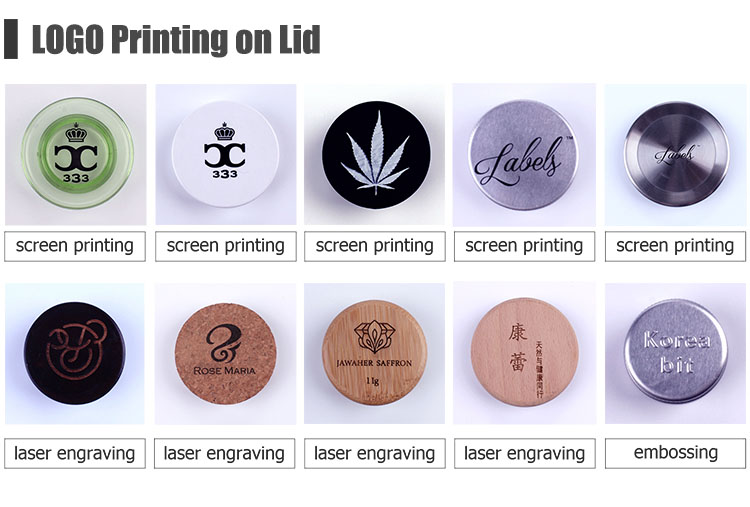

1.ACL printing, silk printing as well as frost printing.

2.Accessories of capsules, such as plastic, aluminum and metal closures and insert wooden stoppers, are also available in UPC. |

The classification and use of glass bottles:

There are many types of glass bottles and cans. According to the conditions of use, they can be divided into recycled bottles and non-recycled bottles (one-time bottles); according to the manufacturing method, they can be divided into molded bottles (bottles formed by models) and Control bottles (bottles made of glass bottles); according to the way, they are divided into food packaging bottles, medicine bottles, cosmetic bottles, cultural and educational supplies bottles, etc. But generally it can be classified into two categories: ampoules (small-mouth bottles) and thick-neck bottles (large-mouth bottles).

1, narrow neck glass bottle (small mouth bottle)

Any bottle whose inner diameter is less than 30 mm is called an ampoule, which is used to contain various liquid substances. Glass bottle my country’s traditional beverage packaging container, glass is also a kind of packaging material with a long history. With many packaging materials pouring into the market, glass containers still occupy an important position in beverage packaging, which is inseparable from its packaging characteristics that other packaging materials cannot replace.

2, thick-necked glass bottle (large-mouth bottle)

Bottles and cans with a neck inner diameter greater than 30 mm, used to hold block, powder and paste items.

Basic requirements for glass bottles and cans

According to different uses, various glass bottles and cans have their corresponding technical regulations. Generally speaking, the following basic requirements should be met:

1. In terms of glass quality, glass should melt well and uniformly, and avoid defects such as stones, streaks, and bubbles as much as possible. Colorless glass must have high transmissivity, and colored glass must be stable in color and able to absorb light waves of a certain wavelength.

2, physical and chemical properties

2.1. The glass should have a certain degree of chemical stability (explanation: stable and stable; no change), and cannot interact with the contents to affect its quality.

2.2. Glass bottles and cans should have a certain degree of thermal stability, and the loss rate should be extremely small.

2.3. Glass bottles and jars should have a certain degree of mechanical strength, vibration, impact, pressure, etc.

- In terms of forming quality, to ensure that it can be broken during sterilization and other heating or cooling processes to withstand internal pressure and encountered during transportation and use. Glass bottles and cans should be formed according to a certain volume, weight and shape. There should be defects such as distortion, uneven surface, cracks and underfullness. The glass distribution should be even, and no part of it should be too thin or thick, especially the mouth should be smooth and flat to ensure sealing.

Product process:

Packing and Shipping: